Redwood is really brittle and the LS wood is especially so!

Make very sure that your cutter is clean and sharp, and that your power

tool is running well -- up to speed, powerful enough, and without

bearing slop. Scoring the grain with a blade would be a good move, but I

haven't found it necessary.

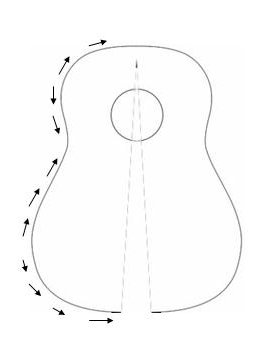

I shellac the edges, rout fairly slowly (1"/second), with an uphill cut. Most

importantly, I don't attempt to rout the whole purfling depth (Or is it

width?) in one pass. I freehand the cut, keeping the guide clear of the

body by a little bit, then go back and finish with the guide bearing riding

against the sides. If you wanted to, you could rout with a larger guide

bearing, then switch to the smaller, final size for the last cut.

And don't even think about using CA glue! It will almost always discolor

the end grain despite all efforts to seal it.

|